- Johri Bazar, Jaipur, Rajasthan

- GST NO. : 08AADPO9847L1ZY

- +91-6378792945, +91-9829018310

Faceting Machines

Leading Exporters and Wholesaler of Advanced Gem Faceting Machine, Commercial Faceting Machine, Concave Faceting Machine, Gem Faceting and Polishing Machine, Gemstone Calibration Machine, Girdle Calibration Machine and Trim Saw Grinder Combo from Jaipur.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Length x Width x Height | 460 mm X 360 mm x 400 mm |

| Motor spindle speed | Variable (0-3000 rpm) |

| Motor power | 220 Watts |

| Lap Diameter | 200 Mm (8”) |

| Power supply | AC 220 volts or AC 110 Volts |

| Net weight | 18 kg |

Preferred Buyer From

| Location | Worldwide |

FEATURES:

- The machine is powered by a direct-drive 220 watt brushless DC (BLDC) motor. BLDC motors are the highest-standard DC motors popular for their long life and precise speed control. The motor offers variable speeds up to 3000 RPM.

- Accurate angle adjustment with a clear indicator and a precision of 1 decimal place.

- Convenient and quick index adjustment. The design allows changing of index quickly with single-handed use. This makes faceting and polishing fast and convenient. The machine comes with a 96 indexing gear installed and a spare 72 indexing gear.

- A cheater adjustment wheel is provided in the facetor for those fine adjustments to the index, sometimes necessary to produce perfect facets.

- The base plate is an 8mm thick sturdy and finely ground industrial-grade fabricated Aluminium. So you can be assured the machine is mounted on a steady base.

- Doping is fast and precise. The machine comes with a set of brass dop sticks that are keyed. Therefore, they are locked in the doping chuck in the exact position every time.

- The indicator dial indicates whether the stone has been cut at the exact angle. The dial indicator reading will show a non-zero reading if the angle of cut on the stone is different from the machine’s angle. A zero reading indicates a perfect angled cut is achieved. This comes in quite handy especially if you are a beginner.

- The mast can be loosened, moved, and tightened easily. Its ground finished so the faceting unit can be moved up and down smoothly. It is equipped with a fine height adjustment knob on top.

- The machine is equipped with a drip water system with an adjustable hose and flow control.

- The machine comes with a white light powerful LED lamp with an adjustable gooseneck.

- Cutting & polishing the girdle is super easy on the machine. Also, the facetor comes with a setting for free rotation. This is very handy for making smooth round girdles.

- Cutting & polishing the table of the stone can be easily done using a 45-degree adapter that comes with the machine. The adapter essentially reduces 45 degrees from the reading on the angle indicator of the machine. Therefore, to achieve a 0-degree angle (which is required to make the table), the machine can be set at 45 degrees while using the 45-degree adapter.

- A water drainage outlet is provisioned on the side of the base. Water drains from the bottom of the splash guard to this outlet.

ACCESSORIES SUPPLIED WITH THE MACHINE:

- 1 Pc. 200mm (8") Zinc polishing lap.

- 2 Pcs. 200mm (8") Diamond lap for grinding.

- 4 Pcs. 25-carat diamond grit pack

- 1 Pc. Aluminum master lap for backing the diamond lap.

- 1 Pc. Brass dop stick set (with various shapes and sizes)

- 1 Pc. 45-degree table adapter

- 1 Pc. Dop transfer jig

- 1 Pc. Drainage hose

- 1 Pc. Dial indicator

- 1 Pc. Led Lamp

- 1 Pc. Superglue for doping

- Toolkit

SPECIFICATIONS:

- Length x Width x Height: 460 mm X 360 mm x 400 mm

- Motor spindle speed: Variable (0-3000 rpm)

- Motor power: 220 Watts

- Lap diameter: 200 mm (8”)

- Power supply: AC 220 volts or AC 110 Volts

- Net weight: 18 kg

ADVANTAGES OVER OTHER MACHINES:

- It’s a feature-packed machine. It has almost everything you will ever need to make great faceted stones.

- It comes with an unparalleled set of accessories included. So you won’t have to spend a single penny more to get you started and working for a long time.

- It’s beginner-friendly. We let some amateur lapidary artists give this machine a try and the single biggest feedback we received is it’s the easiest and most convenient faceting machine they have ever used. A lot of them started pursuing the hobby again!

- Making preforms, girdles, and tables on this machine is a breeze.

- Despite the features and an unrivaled price point, we pledged to not cut any corners. We use the best-in-class BLDC motor, industrial-grade materials like aluminum, stainless steel, and precise machining techniques. Credit to our efficient team of engineers.

WARRANTY & SUPPORT

- 1-year manufacturer warranty (Does not cover physical damage and consumables).

- Installation and operation support.

- Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

INTERNATIONAL CUSTOMERS & SHIPPING

- For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

- Our logistics partners are DHL & FedEx. If any of these have operations in your country, we should be able to ship the products to you.

- The shipping of this faceting machine is insured.

- Time for shipping varies depending on the shipping region but usually, it takes not more than 10 business days to be delivered anywhere in the world, once it’s dispatched. The dispatch times vary depending upon stock availability.

PACKAGING

The machine is shipped in a sturdy honeycomb box.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Capacity | 6 People |

| Driven Type | Electric |

| Automation Grade | Automatic |

| Voltage | 220V |

| Machine Weight | 175 kg |

Preferred Buyer From

| Location | Worldwide |

This machine runs on 220V but can be made to run on 110V if required.

Includes the following:

- Faceting Table 6 Seater

- 6 Facetors & Housing for the Plates

- Electric Motor 1/2 HP

- 8" Diamond Plate 600# & 1200# 1 each (with Backing plates)

- 8" Polishing Plate Copper & Zinc 1 each

- Transfer Fixture and Table Polisher 1 each

- Dop Sticks 100 Dops

- Dop Stick Stand

- Table Polisher

- Overhead Lighting System

Total Net Weight : 175 Kgs.

| Business Type | Exporter, Supplier |

| Power Type | Electric |

| Usage/Application | Gemstone Faceting, Cutting And Polishing, Jewellery Making |

| Voltage | 220 V |

| Weight | 145 kg |

| Material | Mild Steel |

Preferred Buyer From

| Location | Worldwide |

This machine runs on 220V but can be made to run on 110V if required.

Includes the following:

- Faceting Table 4 Seater

- 2 Facetors & Housing for the Plates

- Electric Motor 1/4 HP

- Diamond Concave Roller 600# & 1200# 5 each

- Polishing Concave Roller Copper 1 each

- Overhead Lighting System

Total Net Weight : 145 Kgs.

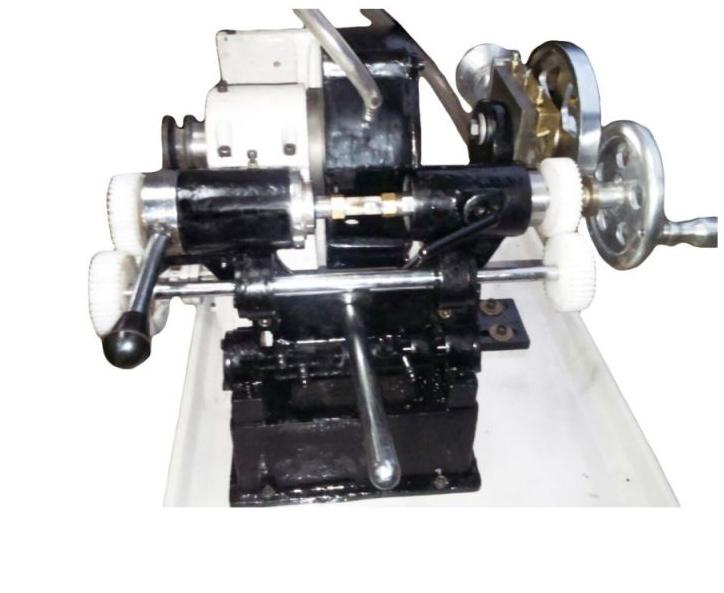

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Height X Width X Depth | 460 Mm X 700 Mm X 450 Mm |

| Motor Spindle Speed | 700-1425 Rpm |

| Lap Diameter | 8” for the Bigger Lap and 6” for the Smaller One |

| Power Required | 180 Watts, Ac 220 Volts / 110 Volts |

| Net Weight | 45 Kg |

Preferred Buyer From

| Location | Worldwide |

Features:

- The motor is isolated from the faceting unit and rotation of the laps is facilitated using a belt between the motor and the faceting unit via an idler pulley and 2 step pulleys (one below each splash guard).

- The idler pulley can be used for tightening the belt. The motor plate can also be moved in and out for this purpose.

- The 2 step pulleys have multiple steps of different diameters that are used to control the rotation speed.

- The facetor unit consists of a metal handpiece (with a rubber grip) that comes with an indexing gear at its end and 3 D-blocks for angle adjustment. Each of these D-blocks has an angle protractor that can be locked at different angles at which the stone has to be cut and polished. These are made of high-quality Bronze and Brass components.

- Angle adjustment on the protractor of the D-block is easy and precise. It comes with divisions of 1° from 0-90, allowing the stone to become completely horizontal or vertical with respect to the lap.

- The facetor unit is mounted on a vertical mast and can be moved up or down for height adjustment or even lifted off entirely for setting-up or inspection.

- The mast can be moved in and out towards the laps (and fixed, once done) to change the position where the gemstone should be applied on the lap.

- The facetor handpiece can be easily moved from one lap to the other. The movement is smooth and facilitated by ball bearings.

- The indexing method for the facetor is simple. The indexing gear comes with a standard 64 divisions (can be 96 divisions if requested) to control the position of facets on the stone and can be adjusted to achieve different shapes.

- The motor and faceting unit is mounted on a heavy base made of cast iron with zinc-coated steel legs and rubber grips to ensure stability and balance during rotation, which is very important to get precise results.

- Both splash guards are removable. This can come in handy when faceting and polishing the girdle of the stone. The stone can be applied purely horizontally to the laps in this case.

- A separate table polisher is installed around the polishing splash guard for polishing the table for your stone.

- The machine has a compact form factor which makes it portable and easy to use.

Accessories supplied with the machine:

- 1 Pc. 6" Copper polishing lap

- 1 Pc. 8" Diamond polishing lap (#600)

- 1 Pc. Aluminum master lap for backing the diamond lap.

- 150 Pcs. Metal Dop sticks (75 for Crown side + 75 for Pavilion side)

- 1 Pc. Facetor (Consists of a metal handpiece with an indexing gear and 3 D-blocks)

- 1 Pc. Dop transfer jig for transferring the stone from pavilion side to the crown side and vice versa

- 1 Pc. Table polisher

- 2 Pc. 25 Ct. Diamond Powder Pack (#14000 and #8000)

Working:

- The gemstone is attached to the dop stick of the facetor handpiece with the help of a glue. You can choose to either do the pavilion side or the crown side first. Attach the stone accordingly.

- The other end of the facetor handpiece has an indexing gear. This end is placed and locked on any of the D-blocks set at the desired angle.

- Once the dop stick is set up with a gemstone and placed on a D-block with the desired angle, the gem can be applied to the rotating grinding lap for faceting.

- The indexing gear can be rotated and set at different values to work on different facets.

- The handpiece can be transferred to a different angled D-block and the same process can be repeated to get different-angled facets if required.

- After faceting is complete, the handpiece can be moved to the polishing lap and the same process can be repeated for polishing your stone.

- Once you have completed faceting and polishing either the pavilion side or the crown side of the stone, use the transfer jig provided to change the orientation of the stone for faceting and polishing the other side.

- Once the stone is attached using transfer jig, repeat the above process.

Advantages over other machines:

- It is a solid value-for-money gem faceting machine that doesn't compromise on functionality and quality.

- It is the most versatile gem faceting and polishing machine that takes care of almost every aspect of faceting and polishing of gemstone.

- It has a double-wheel design as opposed to a single-wheel design that most other faceting machines boast.

- As a result of the double-wheel design, it's convenient to grind and polish your stone simultaneously without having to change between grinding and polishing laps.

- It comes with 3 angle protractors as opposed to only 1 in most other machines.

- The 3 D-blocks can be pre-set with 3 different angles for faceting and polishing, which is a very common requirement.

- As a result of having 3 pre-set angles, the chance of error that might occur while changing the angle every time is significantly reduced.

- It comes with all the basic accessories that are required to start faceting and polishing of your gemstone right away and even more.

Customer Support:

- We truly believe in and live by the customer-first approach in our company. You can be assured of quality support should you ever need any help in operating or installing the machine. Just drop us an email, write to us via contact us page or initiate a chat from our website, we will be at your disposal.

Shipping info:

- The machine usually ships within a day or two from the date of order and is usually delivered within 10 working days across the world. However, the delivery time and shipping charges may vary depending upon your location

Packaging:

The machine is safely packed in a wooden box to prevent any damage during shipping.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Height | 470 mm |

| Width x depth | 550 mm x 650 mm |

| Lap Diameter | 200 mm |

| Cams: Round | Ovals, Square, Octagon, Heart, Pear, Marquise, Trillion, |

| Dop | 8 mm Dia. 50 mm Length |

| Electric Motor | Spindle Motor 180 watt, AC 220 volts (or 110 Volts) |

| 50 watts, AC 220 Volts (or 110 Volts) | Coolant Motor |

| Net Weight | 75 Kg |

Preferred Buyer From

| Location | Worldwide |

The machine will run on 220V but can be made to run on 110V if requested. It is a high-quality machine for all types of Gemstones. It can be used to manufacture precision goods.

Accessories included:

- 4 pc. Cams

- 2 pc. Diamond Discs

- 1 pc. Master lap

- 75 pcs. Dop sticks

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Height | 470 mm |

| Width x depth | 550 mm x 650 mm |

| Wheel Diameter | 150 mm |

| Electric Motor | Spindle Motor 180 watt, AC 220 volts |

| Coolant Motor | 50 watt, AC 220 Volts |

| Net Weight | 65 Kg |

Preferred Buyer From

| Location | Worldwide |

The machine will run on 220V but can be made to run on 110V if requested. It is a high-quality machine for all types of Gemstones. It can be used to manufacture precision goods.

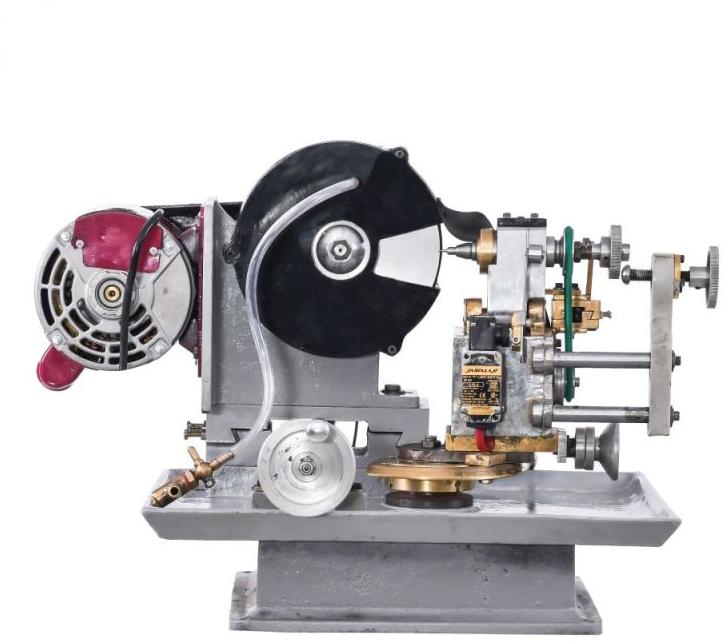

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Height x Width x Depth (Approx.) | 20” X 25” X 17” |

| Motor Spindle Speed | 2800 RPM |

| Motor HP | 1/2 HP |

| Lap Size | Up to 8” |

| Lap Arbor | 1/2” |

| Sawblade Size | 4”-6” |

| Saw Arbor | 20mm, 5/8” |

| Electric Supply | 220 Volts, 110 Volts |

| Net Weight | 35 Kg |

Preferred Buyer From

| Location | Worldwide |

FEATURES OF COMBO MACHINE:

- The machine is great for cutting and grinding cabochon preforms, or fine trimming and pre-polishing faceted stones.

- The saw accepts 4”-6” saw blades and grinder up to 8” grinding laps.

- This saw grinder combo is backed by a solid and powerful 0.5 HP, 2880 RPM motor which is ideal for sawing and grinding all kinds of rocks.

- The saw arbor is available in two sizes, 20 mm or 5/8” to best suit your needs. The arbor for the grinder is a standard 1/2” arbor.

- There is a dedicated water system for both the saw and the grinder. The water system includes an inlet pipe that can be connected to a water supply source. This pipe carries water across the high-quality brass valves that control the flow of water for each application.

- The machine incorporates an adjustable saw blade guard to protect saw blades and guard against water splashes. It can be moved up & down, in & out to adjust for variations in the saw blade size.

- The saw table is also adjustable to position it perfectly for different-sized saw blades and support your hands comfortably while operating the machine.

- A proper drainage system is provided at the base of the machine. It comes with drainage pipes to keep the mess to a minimum. Also, a water blocker has been installed on the base to prevent water flow towards the motor housing.

- The motor housing ensures that the motor remains safe and there’s no direct contact with the motor. Sufficient provisions have been made in the housing for heat dissipation when running for longer periods.

- The machine has a stainless steel body, utilizing the best quality steel which is indestructible, and lightweight. Resultantly, the machine becomes sturdy, durable, long-lasting, and easy to handle.

- The base of the machine nestles on sturdy shockproof legs to minimize vibrations. This provides stability for those fine and precision cuts.

ADVANTAGES OVER OTHER SAWS/GRINDERS:

- It is an ideal choice for cutting and fine-grinding valuable, soft, or fragile gemstones. A high RPM (2800) motor ensures the saw blade and grinding disc run true to provide unmatched accuracy and precision.

- You get both sawing and grinding functionalities in a single machine which is not only extremely convenient but also proves to be a great value as you won’t have to invest in two separate machines.

- The machine has a compact form factor and can be easily set up on a workbench table.

- It comes completely set up with all the necessary accessories and supplies and doesn’t require any assembling.

- Our team of adept engineers designed this trim saw grinder combo with years of experience to deliver a silent and almost vibration-free operating experience.

- The machine is corrosion and rust-free due to the stainless steel body. It can be easily cleaned without any fuss.

WHAT’S INCLUDED:

- Complete machine with the motor

- 2 X 8” Diamond Flat Lap (#600 & #1200)

- 2 X Sawblade (5” & 6”)

- 3 X Inlet Pipe

- 1 X Drainage Pipe

- 1 X Water pump

- 1 X Toolkit

SPECIFICATIONS:

- Height x Width x Depth (Approx.): 20” X 25” X 17”

- Motor Spindle Speed: 2800 RPM

- Motor HP: 1/2 HP

- Lap Size: Up to 8”

- Lap Arbor: 1/2”

- Sawblade Size: 4”-6”

- Saw Arbor: 20mm, 5/8”

- Electric Supply: 220 Volts, 110 Volts

- Net Weight: ~35 Kg

WORKING GUIDE:

- The saw requires the stone to be fed by hand. You must ensure that your vision is in a direct line with the saw blade to know if you’re feeding the stone straight. You can put a mark on the area where the stone needs to be cut for cutting perfectly. This marked line should be put straight with the cutting blade.

- It’s generally advised to wear glasses or face shield, apron, and gloves for safety precautions while working with the machine.

- It is critical to select suitable and appropriate saw blades to meet the required cutting results. You may explore diamond sawblades here.

- It is necessary to select the right grit lap for getting the grinding job perfectly done on the machine. You may explore our diamond laps here

- The machine should be cleaned regularly to remove sawdust or any other particles. The tray around the blade should also be kept clean of any debris as it can result in deflecting the stone.

- Allow the saw blade on the to cut steadily. It means that the cutting should not be forced with high pressure.

- Whenever you’re grinding, pressure or force should not be applied on the lap. The process of grinding should be steady and smooth. Otherwise, it may slow down the rotation speed of the lap and as a result, may lead to flat spots on the stone.

- As a safety measure, the power supply is disconnected before changing the saw blade or the grinding lap on the machine.

- If you’re a beginner, then it is advised to mount the stone onto a dop stick for fine and safe grinding operation. However, if you prefer using your hand then it’s recommended to hold your gemstone with the first four fingers of the dominant hand. This will allow you to have more control while grinding.

WARRANTY & SUPPORT:

- 1-year manufacturer warranty (Does not cover physical damage and consumables).

- Installation and operation support.

- Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

SHIPPING:

- The machine is shipped in a sturdy honeycomb box packaging.

- Time for shipping varies depending on the shipping region but usually, it takes around 5-7 business days to be delivered anywhere in the world, once it’s dispatched. Dispatch time varies depending upon stock availability.

- The shipping is insured.

- The machine is manufactured in India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.