- Johri Bazar, Jaipur, Rajasthan

- GST NO. : 08AADPO9847L1ZY

- +91-6378792945, +91-9829018310

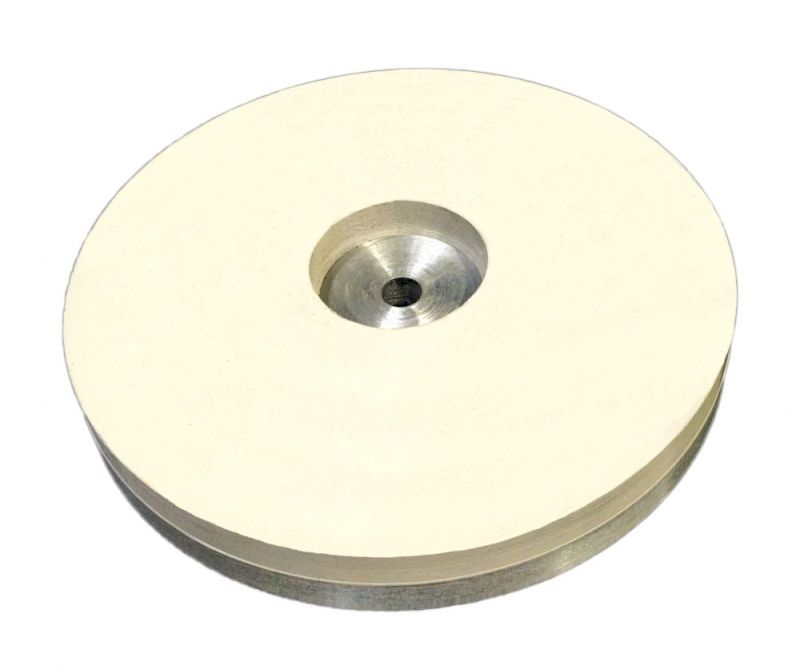

Faceting & Polishing Laps

Leading Exporters and Wholesaler of Cerium Oxide Polishing Lap, Chrome Oxide Polishing Lap, Copper Polishing Lap, Corundum Polishing Lap, Flat Diamond Lap, Girdle Polishing Chrome Oxide Lap, Tin Lap, Ultra-thin Diamond Saw Blade and Zinc Polishing Lap from Jaipur.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Color | Orange |

| Packaging Type | Box |

| Country of Origin | Made in India |

| Purity | 99.99% |

| Usage/Application | Gemstone Polishing,Jewellery Making |

| Diameter | 8 |

Preferred Buyer From

| Location | Worldwide |

Features

- Made with high-grade Cerium Oxide.

- Perfect for polishing soft gemstones like opals, glasss, etc.

- Ideal for any stone with hardness below 6.6 on the Moh's scale.

- Backed by a strong Aluminum base, the lap has a sturdy construction and lasts long

- Perfectly flat and parallel to the surface to ensure great balance and accuracy.

- Available in standard 8" diameter.

- It comes with a standard 1/2" arbor.

- We can custom make these laps in your desired dimensions. Contact us for a custom order.

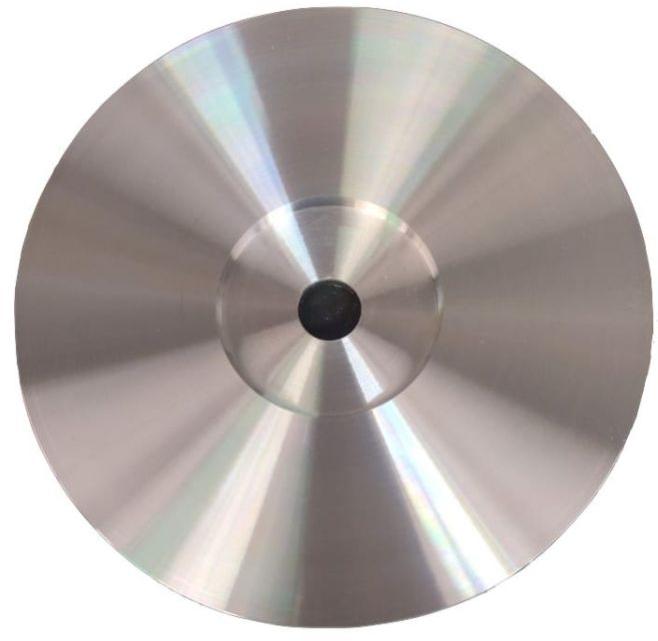

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Diameter | 6” And 8” |

| Arbor | ½” |

| Depth (Polishing Region) | 13.55mm |

| Overall Depth | 27mm |

| Ideal Running Speed | 1800 RPM |

| Compound | Chromium Oxide #600 (Standard model), Chromium Oxide #600 + Diamond Compound #50,000 (Premium Model) |

Preferred Buyer From

| Location | Worldwide |

FEATURES OF CHROME OXIDE POLISHING LAP:

- Chromium oxide is a green-colored, hard lapidary polishing agent, that is the most effective for polishing gemstones.

- Chromium Oxide is an ideal choice for polishing softer gemstones that have hardness from 5-7.5 on Moh’s scale.

- The polishing lap comes infused with the chromium oxide polishing powder and diamond compound (premium model), hence there is no requirement of charging the lap with any other polishing compound before usage.

- Chromium oxide lapidary polishing lap ensures scratch-free polish that provides a mirror-like surface to the gemstones.

- For an Emerald cutter, this lap is the perfect answer for wholesome, easy, fast, clean, and satisfactory polishing of Emeralds.

- It also has the ability to function on a wide variety of gemstones such as polishing Emerald, Aquamarine, Beryl, Tourmaline, Tanzanite, and other similar stones.

- The chromium oxide lap baseplate is machined with strong aluminum, which gives it a sturdy construction and the ability to last long.

- This polishing lap only requires drips of water on the surface while functioning, which works as a coolant so that overheating of the lap is avoided.

- The lapidary polishing lap has been manufactured with the utmost precision to provide a perfectly flat and parallel to the surface lap. This ensures great balance and accuracy for smooth, superior quality lapping of a gemstone.

- The lap needs to be dressed from time to time in order to maintain the plane and smooth surface for lapidary polishing. The best results will be achieved using a dressing stick that delivers perfect results.

- It is available in two variant qualities that are Standard and Premium (impregnated with diamond compound for even better polishing results) to suit your needs. Check out our complete range of polishing and faceting supplies here.

ADVANTAGES OVER OTHER LAPIDARY POLISHING LAP SUPPLIES:

- This lap is a one-of-a-kind polishing and faceting supplies that is charged with chromium oxide, differentiating it from the conventional polishing laps made of compounds such as zinc, tin, etc.

- Before usage, the lap does not require to be charged with any additional agents. This makes the lapidary polishing and faceting process easier, effortless, and convenient as there is no risk of the polishing agent/powder seeping into the gemstones through cracks or nicks. This avoids deterioration of the quality and value of gemstones. Using chromium oxide lap is a far better and an elegant polishing process for gemstones.

- The quality of high-concentration and reduced friction contributes to the superior quality of the polishing laps.

- Another point that makes this polishing lap stand out from other versions of lapping with chromium oxide is that it does not leave green stains on clothes and fingers. Hence, you don’t need to worry about any kind of a mess.

- It is guaranteed that it will outperform other kinds of lapidary polishing supplies to give you unsurpassed quality results of polishing gemstones.

- It imparts a rapid, fast-paced, yet reliable quality performance for desired results of polishing gemstones and brings versatility to the whole process.

- This lap is a valuable investment and proves to be cost-effective in the long run, due to its longer life and better polishing.

SPECIFICATIONS:

- Arbor: ½”

- Diameter: 6” and 8”

- Depth (Polishing Region): 13.55mm

- Overall Depth: 27mm

- Ideal Running Speed: 1800 RPM

- Compound: Chromium Oxide #600 (Standard model), Chromium Oxide #600 + Diamond Compound #50,000 (Premium Model)

USER GUIDE/THINGS TO KEEP IN MIND:

- Best results from these lapidary polishing laps for faceting are obtained when you put the least pressure while polishing valuable gemstones such as Emerald, Quartz, Jade, Garnet, etc. It should be such that constant contact is maintained. High pressure could lead to scratches and chipping away of the top polished layer.

- The surface of the polishing lap should be constantly lubricated with water to keep the surface moist, as heat is absorbed in the process. Hence, the lap will work efficiently for a longer time.

- You need to be aware of the type of compound of the polishing and faceting lap that will be ideal for your choice of gemstone. It varies according to the hardness and type of stone. Chromium oxide is utilised best for polishing gemstones such as Emerald, Quartz, Garnet, Jade, Beryl, Tourmaline, Peridot, Feldspar, and other similar stones. Check out our complete range for polishing laps here if you are looking for a different polishing compound.

- It is imperative to always keep the gemstone and polishing lap clean to achieve a superior quality of shine and polish of the gemstone.

- The room chosen for lapping should also be free of any dust to avoid even the minutest of scratches and dirt from the gemstone.

- We suggest that the lap speed should be moderate, i.e. around 1500 RPM as high speed leads to more stock removal of the gemstone being polished.

- The dressing of the lap should be done carefully to achieve a true plane surface as it determines the quality of the polished stone.

SHIPPING INFORMATION:

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched.

- The shipping of our green chromium polishing lap is insured.

- For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Diameters | 6" and 8" |

| Arbor | 1/2" |

| Type | Copper Polishing Lap |

| Color | Copper |

Preferred Buyer From

| Location | Worldwide |

Features

- Made with high-grade Copper for excellent polishing.

- Perfectly flat and parallel to the surface to ensure great balance and accuracy.

- Can be used for both pre-polishing and final polishing.

- Can easily be charged with diamond grit or other suitable polishing compounds

- Available in the standard 6" and 8" diameters with a 1/2" arbor, these Copper laps can also be custom made in your desired dimensions. Contact us for custom sizes.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Arbor | ½” |

| Diameter | 8” |

| Depth (Polishing Region) | 8mm |

| Overall Depth | 22mm |

| Ideal Running Speed | 1800 RPM |

| Compound | Diamond |

Preferred Buyer From

| Location | Worldwide |

FEATURES OF CORUNDUM POLISHING LAP:

- Corundum gemstones are known for their toughness and hardness, which are polished with an even harder material, i.e. diamond abrasives.

- The polishing lap is made of highest grade RVD diamonds, and of the finest grit, which is ideal for polishing hard gemstones.

- The diamond compound is already present in the entire layer of the lap uniformly. This means that you do not have to worry about manually applying the polishing compound to the lap.

- The hardness of the diamond abrasives ensures superior surface polish finish to the hard gemstones, whose polishing can be tricky with alternative polishing laps.

- To assure sturdiness of the polishing lap while operating, it is backed by a strong aluminium baseplate.

- The polishing lap is the most productive for hard stones of the Corundum gemstones family. It is ideal for polishing Ruby, Sapphire, and Moissanite.

- An accurate and balanced experience is essential for precise lapping and hence, our polishing lap is made with perfection such that it provides an absolutely flat and parallel surface for polishing gemstones.

- Constant and appropriate quantity of flow of water is required to reduce friction between the polishing gemstone and lap. It also works to minimise the frictional heat while working.

- After prolonged use, the lap needs to be dressed to smoothen and renew the lapidary polishing surface. Usage of a dressing stick is advised for best lapidary polishing.

ADVANTAGES OVER OTHER LAPIDARY POLISHING LAP:

- Our polishing lap is known for its characteristics of easy, fast-paced, and clean lapidary polishing results for hard gemstones.

- The polishing lap comes with compressed and dense diamond abrasives, which ensure that there is no chipping away of the gemstone while polishing.

- There is no need for any external lapidary polishing agent, which protects the quality of gemstones from loose polishing agents seeping into gemstones through cracks or nicks.

- In the long-run, our lap is an economical and cost-effective choice than other lapidary polishing tools available for corundum gemstones.

- The highest quality of material used to manufacture the polishing lap imparts endurance to the lap and hence, it has longer life for continued better polishing results of corundum gemstones.

- It has the ability to outperform and provides unsurpassed quality results over other polishing lapidary supplies, providing you wholesome satisfaction. It does not wear away as fast as that of other suppliers of polishing laps.

- It is easy-to-use and convenient as it can be mounted on to any lapidary polishing machines with arbor hole 1/2”.

- The depth of the polishing region of the lap is 13.55 mm, which imparts a long-lasting life to the corundum polishing lap. More depth provides you the best lapidary polishing experience as it has more polishing area.

USER GUIDE FOR POLISHING LAP:

- While polishing corundum gemstones, it must be kept in mind that the surface of the lap should be constantly supplied with coolant or lubricator that helps In improving the efficiency of polish and prevents overheating of the lap. Water is an ideal choice and its flow should be adequate to aid in the process of polishing.

- This combination of diamond abrasives pressed onto the lap is ideal for hard stones belonging to the family of Corundum gemstones such as polishing Ruby or Sapphire. In order to avail best results, you must understand the type of compound or polishing agent being used in the lap. It differs according to the hardness of the gemstones. You may also check out our complete range of polishing laps here to make an informed choice.

- To effectively polish the gemstone, the stone being polished must be moved across the lap from side to side, keeping it in constant touch with the lap. This helps in maintaining the flat surface of the polishing lap in the long-run.

- It must be ensured that the least amount of pressure is being applied to the gemstone as it prevents chipping away of the top polished layer of the gemstone.

- Our suggestion is to maintain the lap’s speed at a moderate level, i.e. at 1800 RPM. Otherwise, high speed may lead to high stock removal.

- To achieve the finest mirror-like lapidary polish of the gemstone, make sure that the lap is clean after every usage and the gemstone should also be free from dust particles. This carelessness may lead to obtaining scratches on the gemstone.

- The environment where you are polishing the gemstones must also be free from dust particles to avoid deteriorating the quality of gemstones.

- Lastly, once the lap needs dressing, It must be done with precision and care such that a plane and flat surface of the polishing lap is obtained.

SPECIFICATIONS:

- Arbor: ½”

- Diameter: 8”

- Depth (Polishing Region): ~8mm

- Overall Depth: ~22mm

- Ideal Running Speed: 1800 RPM

- Compound: Diamond

SHIPPING INFORMATION:

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched.

- The shipping of our Corundum polishing lap is insured.

- The lap is manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

FEATURES OF CORUNDUM POLISHING LAP:

- Corundum gemstones are known for their toughness and hardness, which are polished with an even harder material, i.e. diamond abrasives.

- The polishing lap is made of highest grade RVD diamonds, and of the finest grit, which is ideal for polishing hard gemstones.

- The diamond compound is already present in the entire layer of the lap uniformly. This means that you do not have to worry about manually applying the polishing compound to the lap.

- The hardness of the diamond abrasives ensures superior surface polish finish to the hard gemstones, whose polishing can be tricky with alternative polishing laps.

- To assure sturdiness of the polishing lap while operating, it is backed by a strong aluminium baseplate.

- The polishing lap is the most productive for hard stones of the Corundum gemstones family. It is ideal for polishing Ruby, Sapphire, and Moissanite.

- An accurate and balanced experience is essential for precise lapping and hence, our polishing lap is made with perfection such that it provides an absolutely flat and parallel surface for polishing gemstones.

- Constant and appropriate quantity of flow of water is required to reduce friction between the polishing gemstone and lap. It also works to minimise the frictional heat while working.

- After prolonged use, the lap needs to be dressed to smoothen and renew the lapidary polishing surface. Usage of a dressing stick is advised for best lapidary polishing.

- ADVANTAGES OVER OTHER LAPIDARY POLISHING LAP:

- Our polishing lap is known for its characteristics of easy, fast-paced, and clean lapidary polishing results for hard gemstones.

- The polishing lap comes with compressed and dense diamond abrasives, which ensure that there is no chipping away of the gemstone while polishing.

- There is no need for any external lapidary polishing agent, which protects the quality of gemstones from loose polishing agents seeping into gemstones through cracks or nicks.

- In the long-run, our lap is an economical and cost-effective choice than other lapidary polishing tools available for corundum gemstones.

- The highest quality of material used to manufacture the polishing lap imparts endurance to the lap and hence, it has longer life for continued better polishing results of corundum gemstones.

- It has the ability to outperform and provides unsurpassed quality results over other polishing lapidary supplies, providing you wholesome satisfaction. It does not wear away as fast as that of other suppliers of polishing laps.

- It is easy-to-use and convenient as it can be mounted on to any lapidary polishing machines with arbor hole 1/2”.

- The depth of the polishing region of the lap is 13.55 mm, which imparts a long-lasting life to the corundum polishing lap. More depth provides you the best lapidary polishing experience as it has more polishing area.

USER GUIDE FOR POLISHING LAP:

- While polishing corundum gemstones, it must be kept in mind that the surface of the lap should be constantly supplied with coolant or lubricator that helps In improving the efficiency of polish and prevents overheating of the lap. Water is an ideal choice and its flow should be adequate to aid in the process of polishing.

- This combination of diamond abrasives pressed onto the lap is ideal for hard stones belonging to the family of Corundum gemstones such as polishing Ruby or Sapphire. In order to avail best results, you must understand the type of compound or polishing agent being used in the lap. It differs according to the hardness of the gemstones. You may also check out our complete range of polishing laps here to make an informed choice.

- To effectively polish the gemstone, the stone being polished must be moved across the lap from side to side, keeping it in constant touch with the lap. This helps in maintaining the flat surface of the polishing lap in the long-run.

- It must be ensured that the least amount of pressure is being applied to the gemstone as it prevents chipping away of the top polished layer of the gemstone.

- Our suggestion is to maintain the lap’s speed at a moderate level, i.e. at 1800 RPM. Otherwise, high speed may lead to high stock removal.

- To achieve the finest mirror-like lapidary polish of the gemstone, make sure that the lap is clean after every usage and the gemstone should also be free from dust particles. This carelessness may lead to obtaining scratches on the gemstone.

- The environment where you are polishing the gemstones must also be free from dust particles to avoid deteriorating the quality of gemstones.

- Lastly, once the lap needs dressing, It must be done with precision and care such that a plane and flat surface of the polishing lap is obtained.

SPECIFICATIONS:

- Arbor: ½”

- Diameter: 8”

- Depth (Polishing Region): ~8mm

- Overall Depth: ~22mm

- Ideal Running Speed: 1800 RPM

- Compound: Diamond

SHIPPING INFORMATION:

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched.

- The shipping of our Corundum polishing lap is insured.

- The lap is manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

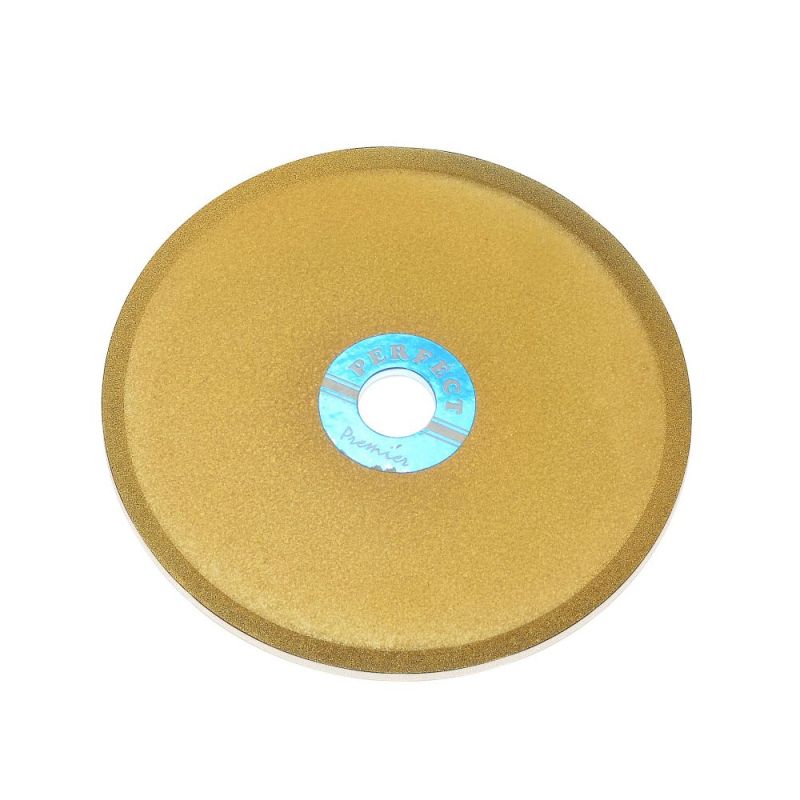

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Arbor | ½” |

| Diameter | 6” and 8” |

| Depth/Thickness | 0.5 mm |

| Ideal Running Speed | 1800 RPM - 3000 RPM |

| Grit | #80, #100, #180, #260, #360, #500, #600, #1200, #1500, #1800, #2200, #3000 |

Preferred Buyer From

| Location | Worldwide |

FEATURES OF FLAT DIAMOND LAPS:

- Diamond laps are circular grinding discs manufactured from high-quality commercial-grade RVD diamond grits, which are electroplated uniformly and firmly.

- The hardest naturally occurring stone available on earth is diamond. This quality of diamond makes Diamond laps the most effective for faceting, grinding, and lapping all kinds of gemstones.

- They feature a standard 1/2” arbor hole.

- They come with a PSA backing plate so that the diamond grinding disc can be easily attached to a backing plate. You have the option of buying an Aluminium backing plate variant in conjunction with the diamond laps available here.

- The steel plate has a surface width of 0.5mm thickness.

- They come in two diameters 6” and 8” as a standard product. However, we provide customisation of sizes on request. Contact us to place a custom order.

- They feature grit size from #80 to #3000, giving you the choice of coarsest grits.

- Water is the best choice as a lubricator for diamond grinding discs during the process of grinding, faceting, or lapping the gemstones.

ADVANTAGES OVER OTHER DIAMOND GRINDING DISCS:

- The diamond grits are embedded with a Nickel electroplating process. Nickel is an element that resists erosion. Hence, these diamond grinding discs do not wear away and provide a clean surface for lapping.

- Electroplated flat diamond laps allow you durability and freer grinding, faceting, and polishing process.

- These diamond grinding discs help obtain a flat surface finish on the gemstones. It ensures that there are no semi-reflective or dull grey surfaces while polishing them at a later stage.

- The surface of the lap, which is composed of steel, has a rigid and robust structure. This provides strength and sturdiness to the diamond laps.

- They are produced with such precision that they are fixed perfectly parallel to the surface. This flat lap provides a smooth surface for balanced and accurate operation.

- These diamond laps do not require any dressing and hence save you the time and effort.

- Diamond abrasives on the laps produce grinding results faster and in fewer cycles than the other laps.

WORKING GUIDE OF DIAMOND GRINDING DISCS:

- To begin with cutting or grinding, where high stock removal is desired, lower grit diamond grinding discs should be preferred. They are aggressive and aid in grinding the gemstones rapidly. The next step where precise and fine grinding is required, finer grit diamond lap should be chosen for the purpose. So the grit size of the diamond laps should be considered based on the gemstone’s value and grinding purpose. We recommend using finer grit flat diamond laps for expensive gemstones so there is minimum wastage of the stone.

- They can be installed either vertically on any suitable lapidary equipment or horizontally on flat lap machines as per your need. To avoid any kind of wobbling of the diamond grinding discs while working, you must ensure that the lap is mounted properly and according to the directions.

- The ideal running speed of the diamond lap should be between 1800RPM - 3000 RPM, which should be decided as per your grinding requirements.

- A sufficient amount of lubrication with water is beneficial while grinding gemstones as it enhances the grinding/lapping process and yields a finer surface finish. It also eliminates overheating of the diamond grinding disc during the process.

- In order to achieve superior results while grinding gemstones, it should be ensured that the diamond grinding disc is clean and dust-free. It avoids the possibility of obtaining minutest patches or scratches on the gemstones.

SPECIFICATIONS:

- Arbor- ½”

- Diameter- 6” and 8”

- Depth/Thickness-0.5 mm

- Ideal Running Speed- 1800 RPM - 3000 RPM

- Grit - #80, #100, #180, #260, #360, #500, #600, #1200, #1500, #1800, #2200, #3000

SHIPPING INFORMATION:

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched.

- The shipping of our flat diamond lap is insured.

- These laps are manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

SUPPORT:

Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Arbor | ½” |

| Diameter | 8” |

| Depth (Polishing Region) | 13.55mm |

| Polishing Area Width | 1 |

| Overall Depth | 27mm |

| Ideal Running Speed | 1800 RPM |

| Compound | Chromium Oxide #600 (Standard model), Chromium Oxide #600 + Diamond Compound #50,000 (Premium Model) |

Preferred Buyer From

| Location | Worldwide |

FEATURES OF CHROME OXIDE POLISHING LAP:

- Chromium oxide is a green-colored, hard lapidary polishing agent, that is the most effective for polishing gemstones.

- Chromium Oxide is an ideal choice for polishing softer gemstones that have hardness from 5-8 on Moh’s scale.

- The polishing lap comes infused with the chromium oxide polishing powder and diamond compound (premium model), hence there is no requirement of charging the lap with any other polishing compound before usage.

- Width of the polishing area is 1".

- Chromium oxide lapidary polishing lap ensures scratch-free polish that provides a mirror-like surface to the gemstones.

- For an Emerald cutter, this lap is the perfect answer for wholesome, easy, fast, clean, and satisfactory polishing of Emeralds.

- It also has the ability to function on a wide variety of gemstones such as polishing Quartz, Jade, Garnet, Aquamarine, Beryl, Tourmaline, Tanzanite, Peridot, and other similar stones.

- The chromium oxide lap baseplate is machined with strong aluminum, which gives it a sturdy construction and the ability to last long.

- This polishing lap only requires drips of water on the surface while functioning, which works as a coolant so that overheating of the lap is avoided.

- The lapidary polishing lap has been manufactured with the utmost precision to provide a perfectly flat and parallel to the surface lap. This ensures great balance and accuracy for smooth, superior quality lapping of a gemstone.

- The lap needs to be dressed from time to time in order to maintain the plane and smooth surface for lapidary polishing. The best results will be achieved using a dressing stick that delivers perfect results.

- It is available in two variant qualities that are Standard and Premium (impregnated with diamond compound for even better polishing results) to suit your needs. Check out our complete range of polishing and faceting supplies here.

ADVANTAGES OVER OTHER LAPIDARY POLISHING LAP SUPPLIES:

- This lap is a one-of-a-kind polishing and faceting supplies that is charged with chromium oxide, differentiating it from the conventional polishing laps made of compounds such as zinc, tin, etc.

- Before usage, the lap does not require to be charged with any additional agents. This makes the lapidary polishing and faceting process easier, effortless, and convenient as there is no risk of the polishing agent/powder seeping into the gemstones through cracks or nicks. This avoids deterioration of the quality and value of gemstones. Using chromium oxide lap is a far better and an elegant polishing process for gemstones.

- The quality of high-concentration and reduced friction contributes to the superior quality of the polishing laps.

- Another point that makes this polishing lap stand out from other versions of lapping with chromium oxide is that it does not leave green stains on clothes and fingers. Hence, you don’t need to worry about any kind of a mess.

- It is guaranteed that it will outperform other kinds of lapidary polishing supplies to give you unsurpassed quality results of polishing gemstones.

- It imparts a rapid, fast-paced, yet reliable quality performance for desired results of polishing gemstones and brings versatility to the whole process.

- This lap is a valuable investment and proves to be cost-effective in the long run, due to its longer life and better polishing.

SPECIFICATIONS:

- Arbor: ½”

- Diameter: 8”

- Depth (Polishing Region): 13.55mm

- Polishing Area Width: 1"

- Overall Depth: 27mm

- Ideal Running Speed: 1800 RPM

- Compound: Chromium Oxide #600 (Standard model), Chromium Oxide #600 + Diamond Compound #50,000 (Premium Model)

USER GUIDE/THINGS TO KEEP IN MIND:

- Best results from these lapidary polishing laps for faceting are obtained when you put the least pressure while polishing valuable gemstones such as Emerald, Quartz, Jade, Garnet, etc. It should be such that constant contact is maintained. High pressure could lead to scratches and chipping away of the top polished layer.

- The surface of the polishing lap should be constantly lubricated with water to keep the surface moist, as heat is absorbed in the process. Hence, the lap will work efficiently for a longer time.

- You need to be aware of the type of compound of the polishing and faceting lap that will be ideal for your choice of gemstone. It varies according to the hardness and type of stone. Chromium oxide is utilized best for polishing gemstones such as Emerald, Quartz, Garnet, Jade, Beryl, Tourmaline, Peridot, Feldspar, and other similar stones. Check out our complete range for polishing laps here if you are looking for a different polishing compound.

- It is imperative to always keep the gemstone and polishing lap clean to achieve a superior quality of shine and polish of the gemstone.

- The room chosen for lapping should also be free of any dust to avoid even the minutest of scratches and dirt from the gemstone.

- We suggest that the lap speed should be moderate, i.e. around 1500 RPM as high speed leads to more stock removal of the gemstone being polished.

- The dressing of the lap should be done carefully to achieve a true plane surface as it determines the quality of the polished stone.

SHIPPING INFORMATION:

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched.

- The shipping of our green chromium polishing lap is insured.

- For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

SUPPORT:

Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Color | Silver |

| Diameters | 6" and 8" |

| Arbor | 1/2" |

| Shape | Round |

Preferred Buyer From

| Location | Worldwide |

Features

- Made with high-grade Tin for excellent polishing.

- Corrosion Resistant.

- Perfectly flat and parallel to the surface to ensure great balance and accuracy.

- Can be used for both pre-polishing and final polishing.

- Can be easily charged with diamond grit or other suitable polishing compounds

- Available in the standard 6" and 8" diameters with a 1/2" arbor, these Tin laps can also be custom made in your desired dimensions. Contact us for custom sizes.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Color | Golden |

| Application | Cutting |

| Type | Diamond Saw Blade |

| Thickness | 0.1 Mm |

| Diameter | 4”, 5”, 6” |

| Arbor | ⅝”,½”, 20mm, 30mm |

Preferred Buyer From

| Location | Worldwide |

FEATURES

- Our diamond saw blade is ultra-thin with a thickness of 0.1 mm. It makes our saw blade almost paper-thin.

- The saw blade is coated with diamond grits uniformly across the rim to provide consistent and effective cutting of the stones.

- The material used to manufacture a thin diamond saw blade is high-grade spring steel, which gives the blade rigidity despite its thinness.

- The ultra-thin diamond saw blade is extremely suitable for expensive stones such as Turquoise, Quartz, Topaz, Opal, Gaspeite, Emerald, Beryls, Glass, and fine Agates to name a few. It is because the blade avoids extreme stock removal of stone while cutting as a result of its extreme thinness. However, you can practically throw any rock at it and get a precise cut.

- The diamond saw blade is perfectly flat and parallel to the surface so that there is no wobbling while operating on the machine.

- The blade runs best when lubricant such as oil or water is used on the blade to prevent overheating and remove unwanted debris.

- The saw blades feature different arbor sizes: ⅝”, ½”, 20mm and 30mm.

- Our saw blade is also available in a range of diameters 4”, 5” and 6” to match your saw machine and lapidary needs.

- For other lapidary needs, you may check out our full range of diamond saw blades according to your needs.

SPECIFICATIONS

- Diameter: 4”, 5”, 6”

- Arbor: ⅝”,½”, 20mm, 30mm

- Thickness: 0.1 mm

USER GUIDE

- It must be kept in mind that the arrow on the saw blade is aligned with the direction of rotation of the shaft, before starting the operation of the saw blade.

- As it’s super-thin, It is advisable to correctly handle its edges so that it does not lose its sharpness and roundness.

- Life of the blade usually depends upon the hardness of the material or stone that you cut. softer the material, longer the life.

- An appropriate amount of coolant should be flown through the diamond blade for improved efficiency of the blade as it reduces overheating.

- To achieve clean cutting results, the lapidary equipment should not be dirty, or dusty.

- Light to medium amount of pressure applied on the saw blade while working is imperative to avoid overheating and overloading of the saw blade.

SHIPPING INFORMATION

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched. It’s usually dispatched within 3-4 business days of order.

- The shipping of our ultra-thin diamond saw blade is insured.

- The product is manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

SUPPORT

Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Material | Zinc |

| Driven Type | Mechanical |

| Shape | Round |

| Color | Silver |

| Specialities | Rust Proof, High Performance, Easy To Operate |

| Arbor | 1/2" |

| Diameters | 6" and 8" |

Preferred Buyer From

| Location | Worldwide |

Features

- Made with high-grade Zinc for excellent polishing.

- Perfectly flat and parallel to the surface to ensure great balance and accuracy.

- Can be easily charged with diamond grit or other suitable polishing compounds

- Available in the standard 6" and 8" diameters with a 1/2" arbor, these Zinc polishing laps can also be custom made in your desired dimensions. Contact us for custom sizes.