- Johri Bazar, Jaipur, Rajasthan

- GST NO. : 08AADPO9847L1ZY

- +91-6378792945, +91-9829018310

Lapidary Equipment

Leading Exporters and Wholesaler of Faceting Machines, Trim Saws / Slab Saws, Ultrasonic Machines, Flat Lap Machines, Cabbing Machines and Tumblers from Jaipur.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Length x Width x Height | 460 mm X 360 mm x 400 mm |

| Motor spindle speed | Variable (0-3000 rpm) |

| Motor power | 220 Watts |

| Lap Diameter | 200 Mm (8”) |

| Power supply | AC 220 volts or AC 110 Volts |

| Net weight | 18 kg |

Preferred Buyer From

| Location | Worldwide |

FEATURES:

- The machine is powered by a direct-drive 220 watt brushless DC (BLDC) motor. BLDC motors are the highest-standard DC motors popular for their long life and precise speed control. The motor offers variable speeds up to 3000 RPM.

- Accurate angle adjustment with a clear indicator and a precision of 1 decimal place.

- Convenient and quick index adjustment. The design allows changing of index quickly with single-handed use. This makes faceting and polishing fast and convenient. The machine comes with a 96 indexing gear installed and a spare 72 indexing gear.

- A cheater adjustment wheel is provided in the facetor for those fine adjustments to the index, sometimes necessary to produce perfect facets.

- The base plate is an 8mm thick sturdy and finely ground industrial-grade fabricated Aluminium. So you can be assured the machine is mounted on a steady base.

- Doping is fast and precise. The machine comes with a set of brass dop sticks that are keyed. Therefore, they are locked in the doping chuck in the exact position every time.

- The indicator dial indicates whether the stone has been cut at the exact angle. The dial indicator reading will show a non-zero reading if the angle of cut on the stone is different from the machine’s angle. A zero reading indicates a perfect angled cut is achieved. This comes in quite handy especially if you are a beginner.

- The mast can be loosened, moved, and tightened easily. Its ground finished so the faceting unit can be moved up and down smoothly. It is equipped with a fine height adjustment knob on top.

- The machine is equipped with a drip water system with an adjustable hose and flow control.

- The machine comes with a white light powerful LED lamp with an adjustable gooseneck.

- Cutting & polishing the girdle is super easy on the machine. Also, the facetor comes with a setting for free rotation. This is very handy for making smooth round girdles.

- Cutting & polishing the table of the stone can be easily done using a 45-degree adapter that comes with the machine. The adapter essentially reduces 45 degrees from the reading on the angle indicator of the machine. Therefore, to achieve a 0-degree angle (which is required to make the table), the machine can be set at 45 degrees while using the 45-degree adapter.

- A water drainage outlet is provisioned on the side of the base. Water drains from the bottom of the splash guard to this outlet.

ACCESSORIES SUPPLIED WITH THE MACHINE:

- 1 Pc. 200mm (8") Zinc polishing lap.

- 2 Pcs. 200mm (8") Diamond lap for grinding.

- 4 Pcs. 25-carat diamond grit pack

- 1 Pc. Aluminum master lap for backing the diamond lap.

- 1 Pc. Brass dop stick set (with various shapes and sizes)

- 1 Pc. 45-degree table adapter

- 1 Pc. Dop transfer jig

- 1 Pc. Drainage hose

- 1 Pc. Dial indicator

- 1 Pc. Led Lamp

- 1 Pc. Superglue for doping

- Toolkit

SPECIFICATIONS:

- Length x Width x Height: 460 mm X 360 mm x 400 mm

- Motor spindle speed: Variable (0-3000 rpm)

- Motor power: 220 Watts

- Lap diameter: 200 mm (8”)

- Power supply: AC 220 volts or AC 110 Volts

- Net weight: 18 kg

ADVANTAGES OVER OTHER MACHINES:

- It’s a feature-packed machine. It has almost everything you will ever need to make great faceted stones.

- It comes with an unparalleled set of accessories included. So you won’t have to spend a single penny more to get you started and working for a long time.

- It’s beginner-friendly. We let some amateur lapidary artists give this machine a try and the single biggest feedback we received is it’s the easiest and most convenient faceting machine they have ever used. A lot of them started pursuing the hobby again!

- Making preforms, girdles, and tables on this machine is a breeze.

- Despite the features and an unrivaled price point, we pledged to not cut any corners. We use the best-in-class BLDC motor, industrial-grade materials like aluminum, stainless steel, and precise machining techniques. Credit to our efficient team of engineers.

WARRANTY & SUPPORT

- 1-year manufacturer warranty (Does not cover physical damage and consumables).

- Installation and operation support.

- Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

INTERNATIONAL CUSTOMERS & SHIPPING

- For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

- Our logistics partners are DHL & FedEx. If any of these have operations in your country, we should be able to ship the products to you.

- The shipping of this faceting machine is insured.

- Time for shipping varies depending on the shipping region but usually, it takes not more than 10 business days to be delivered anywhere in the world, once it’s dispatched. The dispatch times vary depending upon stock availability.

PACKAGING

The machine is shipped in a sturdy honeycomb box.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Color | Silver |

| Usage/Application | Cut & Grind Rocks/Gemstones |

| Grinding Wheel Size | 8" |

| Spindle Speed | 1400 RPM |

| Motor Power | 1/4 HP |

Preferred Buyer From

| Location | Worldwide |

The machine will run on 220V but can be made to run on 110V if requested

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Voltage | AC 220V |

| Power | 1500w/2400w/3200w |

| Frequency | 15KHz—20KHz |

| Dimension | 540mm×500mm×1500mm |

| Material | Mild Steel |

Preferred Buyer From

| Location | Worldwide |

5 pcs steel molds supplied with the machine

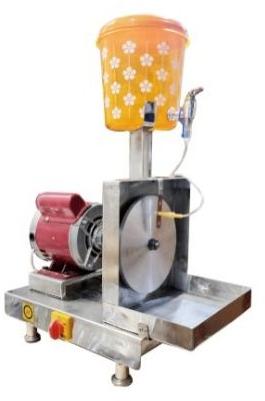

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Condition | New |

| Automatic Grade | Automatic |

| Height x Width x Depth | 18” X 15.5” X 12” |

| Motor Spindle Speed | 1440 RPM |

| Motor HP | 1/4 HP |

| Lap size | Up to 8” |

| Arbor | ½” |

| Electric Supply | 220 Volts, 110 Volts |

Preferred Buyer From

| Location | Worldwide |

FEATURES

- This flat lap machine is a full-featured, vertically oriented machine best suited for fine grinding of gemstones.

- The lap machine is fitted with a high-torque, powerful 1440 RPM direct-drive motor of 1/4 H/P. It is suitable for heavy-duty grinding of all types of gemstones and rocks.

- It is composed of a steel body, which makes it impact resistant and sturdy.

- The machine is designed to fit up to 8” grinding lap with 1/2” arbor hole diameter.

- It utilizes diamond grinding laps, which are easily interchangeable as per the grinding applications, ranging from rough grinding to fine grinding. You may explore the most suitable Diamond grinding laps here.

- This lap machine comes integrated with a functional drip water system to facilitate a smooth and heat-free grinding process.

- The water system of this machine has a flexible valve to regulate and direct the flow of water as per requirements towards the grinding area.

- The design of the machine allows trouble-free access to the outermost edges of the grinding laps for optimum utilization.

ADVANTAGES

- The machine is designed in a unique low profile, which can be easily set up on a workbench table. This allows you to grind your stones with ease and perfection.

- It comes completely set up with all the necessary equipment parts and doesn’t require any assembling.

- It is a versatile machine as it can accept any other grinding laps, provided the grinding lap has the same dimensions.

- The water reservoir can hold enough water to allow you to work uninterrupted for several hours. You won’t have to worry about refilling it continuously. Also, the water coolant system means that there will be no oily mess, no heat build-up, and no dust particles while working.

- This lap machine is characteristic of being durable and light-weight, making it easier to work from anywhere and anytime.

- The experience of working with this flat lap machine is an easy affair with convenience, uncomplicated functions, and effortless maintenance.

- This flat lap machine is bound to provide you many years of unfailing quality service.

WHAT’S INCLUDED

- Complete machine with motor

- Water system

- Toolkit

SPECIFICATIONS

- Height x Width x Depth: 18” X 15.5” X 12”

- Motor Spindle Speed: 1440 RPM

- Motor HP: 1/4 HP

- Lap size: Up to 8”

- Arbor: ½”

- Electric Supply: 220 Volts, 110 Volts

USER GUIDE

- Before you begin working, you should fill in the machine’s water container up to the top. Do not run the water drip until the machine’s started as water may percolate to the motor shaft and ruin it.

- You should always thoroughly clean your stone and machine after every stage or when changing grits of grinding laps. It avoids contamination of the stones as stray particles may lead to scratches.

- You must work in clean environment conditions to stay away from dust particles

- It is necessary to select the right grit lap for getting the grinding job perfectly done on the machine.

- Whenever you’re grinding using a lap machine, pressure or force should not be applied on the lap. The process of grinding should be steady and smooth. Otherwise, it may slow down the rotation speed of the lap and as a result may lead to flat spots on the stone.

- Ensure that the power supply is disconnected before changing to a different grit size grinding lap on the flat lap machine.

- This flat lap machine accepts laps that need to be run with a dewy thin layer of water to reduce the frictional heat while grinding gemstones.

- If you’re a beginner, then it is advised to mount the stone onto a dop stick for fine and safe grinding operation. However, if you prefer using your hand then it’s recommended to hold your gemstone with the first four fingers of the dominant hand. This will allow you to have more control while grinding.

WARRANTY & SUPPORT

- 1-year manufacturer warranty (Does not cover physical damage and consumables).

- Installation and operation support.

- Drop us an email at sales@jewelsntools.comor contact us from the website for any assistance. We’d be quick to respond and glad to help.

SHIPPING

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched. It is usually dispatched within a week from the date of order.

- The machine is shipped in a sturdy box packing.

- The shipping of the flat lap machine is insured.

- The machine is manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Height X Width X Depth: | 15” X 43” X 20” |

| Motor Spindle Speed | 1425 Rpm |

| Motor Hp | 1 Hp |

| Wheel diameter | 8” |

| Lap diameter | 6” |

| Electric Supply | 220 Volts, 110 Volts |

| Net weight | 55 Kg |

Preferred Buyer From

| Location | Worldwide |

FEATURES OF CABBING MACHINE:

- The 8” model of cabbing machine is backed by a 1 HP strong motor. The direct-drive, single shaft motor comes with thermal protected ball bearing and copper windings. It’s designed by our team of technicians for heavy-duty grinding. This ensures long-lasting potentiality of the machine.

- The base of the machine is made of cast Aluminium. It’s durable, sturdy and adds sufficient weight to the machine, which is important to keep it steady and well-balanced while operating.

- The machine sits on a solid wooden board which is water-proof. This ensures it does not get deformed due to prolonged exposure to water. It further helps to maintain the stability of the machine.

- The spacing between the lapidary wheels is ample to establish a comfortable working area to perform cabbing on larger stones as well. This allows you to use even side rims of the wheels without any hindrance.

- The stainless steel hood on the top of the cab machine can be easily raised for inspection, easy mounting/unmounting of wheels, and cleaning, as per your convenience.

- The left shaft of the machine utilises 2 Hard Diamond wheels ( #100, #260 grits) and 1 Soft Resin Bond wheel (#260) which is the coarsest among other Resin Wheels. The right side shaft of the machine utilises 3 Soft Resin bond wheels (#600, #1200, #3000 grits.) An ideal sequence of wheels is achieved with this placement for the cabbing process. It allows you to begin and move from the leftmost wheel for grinding to the next wheel on right for finer process of grinding and polishing.

- The shaft is tapped for ½”-20 at both ends to house spin-on polish heads, aluminium laps, diamond facet laps, polish pads, etc. These laps can be mounted by removing the side covers at the ends and then utilise the laps according to your convenience.

- The cabbing machine consists of a 1” versatile shaft which can accept a variety of 1” arbor hole size wheels such as silicon carbide, diamond wheels, or rubber expandable drums, as per your utility.

- The stainless steel side covers are removable to allow usage of a polishing lap or a felt polishing pad and for easy cleaning and maintenance of the cab machine.

- It has an adjustable drip water system with shut off valves made of Brass to control the flow of water on the wheels. This ensures that the process of cutting cabochons is smooth and avoids overheating of the wheels.

- It also has a systemised drainage system to eliminate the accumulation of draining water in the machine.

- It comes with an in-built adjustable bright LED lamp for optimum vision during cutting and polishing gemstones.

- The speed of the motor is at a steady 1425 RPM, which is an ideal speed required for cutting fine and accurate stone cabochons.

- The edges of the base of the machine are covered with soft pipes. They serve as hand rests while working. This ensures your cabbing experience is pleasant and comfortable.

ADVANTAGES OVER OTHER CAB MACHINES:

- Use of materials like cast aluminum for the base, stainless steel for the hood, and Water-proof wood for the board ensure that our cabbing machine is heavy-duty, lasts long, needs little maintenance and is a valuable investment. Most other machines resort to using a plastic base that isn’t as sturdy and prone to damage or have particle boards that are not water-proof and deform easily on prolonged exposure to water.

- The 8” model of our cabbing machine comes with a 1 HP heavy-duty motor as compared to a ¾ HP on most other machines, which means a more powerful engine for consistent operations and lasting results.

- An added advantage of the motor engine is that it’s a direct-drive motor which means it doesn’t have pulleys or belts to facilitate rotation of wheels. This means that you can apply force on the wheels while cabbing without slowing them down.

- The machine is almost silent while running. It makes your experience more enjoyable and less annoying.

- It comes equipped with one of the best diamond wheels in the industry that are trusted and loved by many across the world.

- It’s priced competitively and is considerably cheaper than similar machines in the market. It proves to be a valuable investment cabbing machine which ensures superior quality results for cabbing.

- The water valves are made of high-quality brass. This makes them last long and not clog easily.

- It is an easy-to-use, maintain, and convenient cabbing machine as it is rust free and requires least effort to clean the machine. This makes it an ideal choice whether you’re an amateur, a hobbyist, or a master of the technique.

- The submersible water pump provided with the machine is a mute pump which ensures that your concentration is not interfered with unnecessary noises while cabbing.

- All the necessary accessories that are required for smooth functioning of your work are provided with the cab machine.

- It is a fully set-up machine, which means you don’t have to worry about manually changing and swapping between diamond and resin-bond wheels for effortless cabbing of cabochon gemstones.

SPECIFICATIONS:

- Height x Width x Depth: 15” X 43” X 20”

- Motor spindle speed: 1425 RPM

- Motor HP: 1 HP

- Wheel diameter: 8”

- Lap diameter: 6”

- Electric Supply: 220 volts, 110 volts

- Net weight: 55 Kg

WHAT’S INCLUDED?

- 1 X Direct-drive, single-shaft Motor 1 HP

- 2 X Hard Diamond Wheels 8” X 2”

- 4 X Soft Resin Bond Diamond Wheels 8” X 2”

- 1 X Diamond Lap 6”

- 1 X Adjustable LED light

- 1 X Submersible Water Pump

- 2 X Water Pipe to connect the pump with the machine

- 8 X Brass Valve (6 at the front for the wheels, 2 at the back for side laps)

- 2 X Drainage pipe

- 8 X Aluminum Spacers

- 1 X Tool kit (Spanners, Screwdriver, Nuts & Bolts)

WORKING OF CABBING MACHINE:

- Ensure that the wheels have been mounted in the correct sequence from left to right. We advise coarser wheels on the left and finer ones on the right.

- Place the pump in a bucket with clean water, connect its pipes to the cab machine and turn it on.

- Attach the drainage pipes to the machine with one end on the openings on the back of the machine and another end in a separate empty bucket to collect drainage water. You may choose to recycle the same water by using a common bucket for pump and drainage.

- It’s advised to mount the stone on a dop stick for safety (especially for smaller pieces). However, you may choose to keep the stone in hand if you are experienced or the piece is large enough for cabbing.

- Turn on the motor and start grinding the cabochon gemstone on the leftmost/coarsest hard wheel. Turn on the water supply for the wheel using the valve on top if required.

- It’s advised to wear an apron while working to avoid getting drenched in water.

- Use the adjustable LED light for better visibility if required.

- Keep checking the stone cabochon intermittently to monitor its shape and polish.

- Now move to the less coarse hard or a soft wheel for finer grinding and repeat the process.

- Once done with grinding, move further right to the finer soft wheels for polishing the stone.

WARRANTY & SUPPORT:

- 1-year manufacturer warranty (Does not include physical damage and consumables).

- Installation and operation support.

- Drop us an email at sales@jewelsntools.com or contact us from the website for any assistance. We’d be quick to respond and glad to help.

SHIPPING INFORMATION:

- Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched.

- The shipping of our cabbing machine is insured.

- The machine ships from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

MOQ : 1 Piece

| Business Type | Exporter, Supplier |

| Tub Size | 22 ID x 1OH |

| Jewelry Capacity | 0.5 Kg |

| Motor HP | 0.12 |

| Motor KW | 0.09 |

| Dimensions in Cm | 28 X 28 X 49 |

| Net Weight | 7 Kg |

Preferred Buyer From

| Location | Worldwide |

Features:

- High-quality fiber body

- Linked polyethylene ensures any polishing media can be used to achieve optimum processing results

- Suitable for a small/medium jewelry unit

- Special rubber mold spring to provide durability

- One year motor guarantee

- Low noise & compact size

- Many types of media can be used.

Four types of polishing media used are:

- Stainless steel media - 7 Kg

- Ceramic media - 3 Kg

- Plastic media - 3 Kg

- Walnut media - 2 Kg